Would you like to use LPR's red pallets for your supply chain? All the answers to your questions can be found here.

- What we do

- Work with us

- Pallet overview

- About LPR

- Sustainability report 2022

- Foreword CEO Gerjo Scheringa

- Strategy business reporting

- Strategy delivering sustainability at scale

- Goals and results

- Brand ambassadors

- Sustainable change agents

- Employee health, training & development

- Green transport

- Lowering temperature washing

- Energy efficiency

- Nestlé sector collaboration

- Automation by Tanzer Solutions

- Aldi UK sustainability solutions

- Stakeholder management

- About Euro Pool Group

- Sustainability report 2021

- Sustainability

- About Us

- Research and development

- Safety and security

- Sustainability report 2022

- More

- MyLPR

- Contact

Frequently

asked

questions

Get all the answers to the questions we are most often asked. If what you need to know isn’t here, please contact us directly or consult our knowledge centre.

About our LPR pallets

We have acquired PEFC certification and have therefore implemented a rigorous chain of custody to ensure that the wood for our wooden pallets comes from forests that are managed ‘sustainably’. By choosing a high quality timber, pallet durability is improved and sections of components parts can be optimized to meet source reduction and loading capacity requirements. In addition, nails design and a nailing plan are selected to obtain efficient performance and thus limit pallet damage during its lifetime. Nails (non-alloy steel) comply with relevant European regulations. Our plastics pallets are made from virgin polypropylene and recycled polyproprylene.

Our pallets are reserved strictly for the FMCG sector, in order to avoid any risk of contamination. LPR’s pallets components, when applicable, are selected and controlled to be safe for use within the food and drinks manufacturing and distribution industry. Nevertheless, the pallet is a tertiary packaging. By definition it is not intended to come into direct contact with goods (in particular unpacked foodstuffs) and does not have conditions to preserve products as applicable to primary or secondary packaging. In addition, to guarantee customers a constant supply of quality standards, pallets are sorted out after each rotation, inspected and repaired when required (timber, spare parts from agreed LPR sawmills and suppliers) by LPR Service Centers according to LPR technical specifications.

The red colour results from a water-based red paint applied on all sides of the palette. To ensure paint quality, LPR authorises the purchase of paint from its service providers and manufacturers only from approved suppliers and on specific product references. Moreover the paint has been selected to be safe for use within the food and drinks industry.

We offer standardized pallets compatible with most food & drink manufacturing and distribution. Our pallets are suitable for all types of production lines and handling equipment. They are also fully compatible with all automated systems.

Upon request, LPR can deliver pallets treated in compliance with the ISPM15 and the related laws applicable in the country of delivery. Only the pallets delivered as treated by LPR to the user are guaranteed as compliant with ISPM15 and related laws of the country of delivery, at the time of delivery.

Our pallets are accepted by all the main retailers in Europe.

Our range of pallets is made up of wooden and plastic pallets. Our handling pallets include all formats commonly used in the FMCG sector : PR080 80x120 ; UK100 100x120, but also half-pallets 60x100 DP610 and Dusseldorf pallets 60x80. We also propose a display pallet called RQP46 (40x60) suited for in-store display building.

We chose to use wooden pallets because wood is a more robust material and also easier to repair. Moreover, the circularity of resources is central to our approach: wooden pallets have a positive end-of-life and can be recycled when they are no longer repairable. We also make sure that we only use wood from sustainably managed forests.

We offer European food manufacturers a pallet rental and management service.

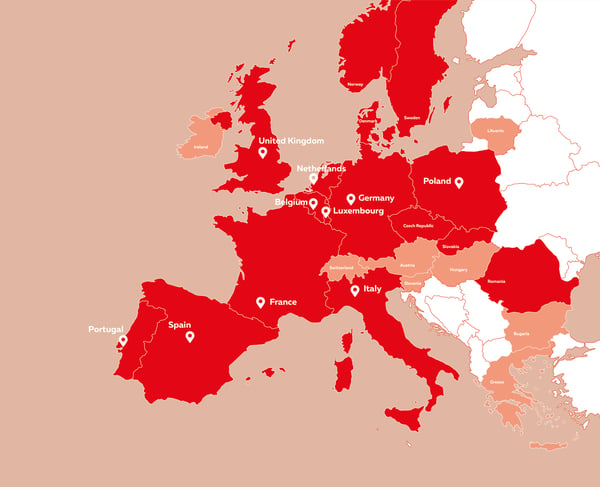

We can be found in Europe. We have subsidiaries in 10 European countries (France, Spain, Portugal, Italy, UK, Ireland, Belgium, Netherlands, Germany, Poland, Romania) and we are able to deliver and collect throughout Europe.

We are PEFC, Ecovadis and ISO 9001 v.2015 certified for our Portuguese and Dutch subsidiaries.

You can submit an application in response to one of our job vacancies via the dedicated page or send us your CV and covering letter.

With LPR, you have access to a personalised customer portal which is a clear, intuitive and comprehensive account management tool. On the portal, you will find information about our pallets, how to place an order as well as easily locate your invoices.

Our transparency. We are transparent about the costs involved in your logistics operation!

We subcontract the manufacturing and repair of our pallets to trusted service providers and suppliers who work to our strict specifications. 134 service centres in Europe handle the sorting, inspection and repair of our pallets and we have approved manufacturers throughout the continent.

We have teams located across Europe who manage the quality processes with our suppliers and service providers. This process is very thorough and allows us to guarantee the quality of our pallets throughout their life cycle.

If you would like to order pallets for the first time, you should contact your local LPR team either via the website or by telephone. If you are already a customer, you can use your MyLPR web portal and place your order. You can then use MyLPR to follow its progress.

Pallets can be delivered the day after you have ordered them.

MyLPR is the LPR customer online portal, accessible 24/7.

Yes, you can order your pallets via the MyLPR web portal.

You can manage all your LPR pallet activities using the portal, including ordering your pallets, tracking your stocks, viewing and downloading your invoices and accessing your reports.

You data is processed in accordance with current regulations established by the General Data Protection Regulation (GDPR). Your data is processed securely with LPR.

There is no additional fee for using MyLPR. It is a service included in our pallet rental and management services.

Once you are a customer, you will receive your login details to connect to the platform. If you still do not have your access, you can contact your account manager.

The concept of circularity is at the heart of all our activity. It is at the centre of our business model and we aim to further maximise this circularity. By sharing the benefits of returnable packaging, we are supporting our customers in reducing their carbon footprint, and in this way we are also encouraging the transition towards a circular economy.

We aim to reduce our impact on the environment by managing truck capacity, working with local suppliers, using the same carrier for inbound and outbound shipments from factories, and using alternative transport such as rail, and other initiatives. In addition, we aim to compensate 5% of our carbon footprint per year through reforestation.

Our pallets have a lifespan of at least five years, and we monitor them until their end-of-life.

Pallets that are no longer repairable are recycled.

Your impact on the environment can be reduced when you switch from one-way pallets to reusable pallets. You can use our Environmental impact reduction simulator to estimate your saving.

We have acquired PEFC certification and have therefore implemented a rigorous chain of custody to ensure that the wood for our wooden pallets comes from forests that are managed ‘sustainably’.

Thanks to Shippeo, it is possible to track loads in real time. Managing your flows has never been so easy!

By combining Shippeo's GPS service and IoT technologies, your logistics tracking will take on a new dimension. Tracing in real time and on the device of your choice.

About Covid-19

Do you have a question about the impact of COVID-19 on our business? Find all our answers in this FAQ.

Despite the sanitary crisis across Europe, LPR has continued to operate its full service offering. The hard work and flexibility of our teams, as well as the close collaboration with our partners, have enabled us to ensure all our deliveries were made – even while demand was at its peak. However, due to the second wave of the virus and legislative measures adopted (or to be adopted), some services we provide to you could potentially be impacted (either delayed or prevented). We would like to reassure both our customers and partners that they will be informed ahead of time, should such a situation occur.

Until now, the transportation of pallets and goods between countries within the EU has been continuously maintained. Longer delays in crossing borders may be seen, depending upon the controls implemented by each Member State. In the event of border closures, we will adjust our logistics solutions and utilise the flexibility of our networks at national level. This is included within our Business Continuity Plan.

We have implemented a number of strategies since the beginning of the sanitary crisis in Europe, which includes: • Organising an internal task force, holding regular meetings to follow the evolution of the situation in each country where we operate, able to make rapid decisions when required. • Updating our Business Continuity Plan. • Providing specific health and safety guidance to employees and to our partners (service centres, pallet manufacturers and carriers) based on the guidelines of the local authorities of each country where we operate and from the World Health Organisation (WHO). • Restricting business travel to only necessary journeys, particularly in respect of international travel. • Implementing flexible remote working to limit the number of employees present in the office and to be able to close offices when necessary. • Providing all LPR employees with mobile equipment allowing the move to remote working with fully secure IT tools. • Organising telephone line transfers so that contact numbers remain unchanged for customers and business partners when employees are working remotely.

Yes, we developed a Business Continuity Plan for all our European subsidiaries. Among other aspects, this plan relies on: • The flexibility of our Service Centre network located across Europe, allowing relocation of pallets and activities to the most appropriate Centre. • The remote accessibility of all our IT systems and equipment, allowing employees to connect safely when remote working. Our Business Continuity Plan is available to our customers upon request.

We have ensured that our transport suppliers follow the recommendations and directives expressed by the government authorities and apply good practices such as: • Carefully following the health and safety instructions of each site where our pallets are loaded/unloaded. • Not have been in contact with an infected person or have travelled to infected areas in the previous two weeks. • Should be healthy. Have no cough, or cold. And most importantly they should not have a fever. • Keep to good “coughing etiquette” (for example, they should sneeze or cough into a tissue, and throw the tissue away) or, if this is not possible, into a flexed elbow. • Interactions between the drivers and the employees of the sites to be limited as much as possible. In any event, drivers should keep to the required distance from the site’s employees (min. 1.5 meters where possible) and not shake hands. • If the driver needs to use site facilities, they should disinfect their hands with an alcohol-based sanitizer or wash their hands carefully with soap and water.

All our employees have received specific instructions based on the guidelines received from the local authority of each LPR operational country and from the World Health Organisation (WHO). All customer facing LPR staff are provided with homologated disposable masks and hand sanitising solution. In addition, all employees visiting customer and business partner sites have been requested to follow the specific procedures of each site. The instructions and equipment provided are continuously reviewed and adapted according to the evolving situation in each country where we operate. Any employee that has been in contact with someone who is suspected or confirmed as having COVID-19 is requested to stay home for the quarantine period defined by each country in which we operate. Any employee that is concerned regarding their health or showing symptoms (including cough, cold, fever etc…) is requested to remain at home, consult a doctor and, if necessary, pass a COVID test.

There is no evidence to date that viruses that cause respiratory illnesses may be transmitted via pallets or any other food packaging. The World Health Organisation (WHO): “Coronaviruses need a live animal or human host to multiply and survive and cannot multiply on the surface of food packages.” (Q&A: Food Safety and Nutrition related to COVID-19 on 14 August 2020) “It is highly unlikely that people can contract COVID-19 from food or food packaging. COVID-19 is a respiratory illness and the primary transmission route is through person-to-person contact and through direct contact with respiratory droplets generated when an infected person coughs or sneezes.” (COVID-19 and food safety: guidance for food businesses on 7 April 2020)

About Brexit and ISPM15

LPR - La Palette Rouge answers your questions about the impact of Brexit on our UK activity.

ISPM15 is a phytosanitary standard applicable to wood packaging material in international trade. Its purpose is to prevent the spread of insects that could negatively affect plants or ecosystems between different geographical areas.

ISPM15 standard has been elaborated by the Secretariat of the International Plant Protection Convention (IPPC) and must be adopted by the contracting parties of the IPPC in their domestic regulations.

For instance, the European Union and UK are contracting parties to the IPPC, and as such, require that the wood packaging materials imported into their territory comply with ISPM15 standard (see Q2 for more details).

Wood packaging materials must fulfil the following requirements in order to comply with the ISPM15:

-

They must be subject to one or more of the approved treatments set out in Annex 1 of the ISPM15.

-

They must be marked as outlined in Annex 2 of the ISPM15 attesting that they have been subject to the required treatments.

The list of countries participating in the IPPC (see Question 1) is available at : https://www.ippc.int/fr/countries/all/list-countries/

Furthermore, national laws may apply as an alternative or complement to the IPPC, so it belongs to each user of wood packaging materials to be aware of the applicable legal requirements.

LPR provides below a non-exhaustive and not necessarily up-to-date analysis of the various geographical areas where LPR operates.

Regulation (EU) 2016/2031 sets out the requirements for the import of wood packaging material (including pallets) from third countries into the EU.

All pallets imported into the EU (loaded or empty) from third countries must be officially treated and marked in accordance with the ISPM15.

It should be noted that pallets exported from the EU (loaded or empty) to third countries may be subject to compliance with the specific phytosanitary requirements of the importing country (such as ISPM15 treatment or phytosanitary certificate). It is therefore up to each user of wood packaging materials to be aware of the legal requirements applicable in the country of import.

Since the 1st of January 2021, all wood packaging material moving between United Kingdom (UK) and the European Union (EU) in both ways must be treated and marked in compliance with the ISPM15 standard. ISPM15 treatment is not required for UK domestic flows.

For the purposes of Regulation (EU) 2016/2031, the following territories are considered third countries: Ceuta, Melilla, Guadeloupe, French Guiana, Martinique, Réunion, Saint-Barthélemy, Saint-Martin and the Canary Islands. ISPM15 treatment is required for wooden packaging from certain regions of the EU (such as Portugal and parts of Spain), in which the presence of the pinewood nematode is possibly recognised (Commission Implementing Decision 2012/535/EU of 26 September 2012).

According to the Spanish law “Orden APA/1076/2018”, all pallets imported to and exported from the Canary Islands (whether loaded or empty) must be treated and marked in accordance with ISPM15 (including from and to the EU).

According to Prefectoral Order No. 2011 - 1479 of 30 September 2011, all pallets imported into Reunion Island (whether loaded or empty) must be treated and marked in accordance with the ISPM15 (including those from the EU). For the purposes of phytosanitary regulations (in particular Regulation (EU) 2016/2031), as the Reunion Island is considered a third country, any pallets sent from these territories to another area of the EU must also be treated and marked in accordance with ISPM15.

There are different variants authorised for the marks indicating that wood packaging material has been subjected to a phytosanitary treatment in accordance with ISPM15 standard. The size, position, font types and marking technics (fire-marking, ink, paint) may vary.

To be valid the marks must include the IPPC symbol, a country code, a producer/treatment provider code and a treatment code (HT for heat treatment).

No additional information is included within the limits of the marking, although this may appear next to the marking. Additional codes and information may appear adjacent to but outside of the border of the mark.

In some cases, marks from different operators may appear on a single pallet.

Control plans and consequences in case of non-compliant imported wood packaging material are mainly framed in each national law and/or decided by local authorities. Possible consequences may include denial of entry of the entire shipment, destruction of the pallet and/or the merchandise being carried.

LPR guarantees that only the pallets it delivers as “TREATED” are compliant with the ISPM15. Once delivered, customers, and more broadly, the users of the pallets, are fully responsible and liable for the proper use of these pallets in accordance with the ISPM15 and the corresponding national laws.

It is henceforth the sole responsibility of the user of a pallet to ensure that it is adequately informed of the applicable phytosanitary laws and regulations, and it is the responsibility of LPR customers to order LPR “TREATED” pallets where required.

LPR has increased the heat-treatment capacities in its partners’ network and has put in place specific procedures, as well as logistical measures, to ensure proper treatment, marking, sorting and stock management.

Customers are nevertheless strongly advised to anticipate their evolution flows by sharing their forecasts with LPR as soon as possible, to allow LPR to secure the heat-treatment capacity and ensure delivery of ISPM15- compliant pallets to fulfil their requirements.

Pallets complying with ISPM15 can be ordered by selecting the option “TREATED” or “TRT” in MyLPR. If the item “TREATED” or “TRT” is not available on MyLPR, please inform your usual LPR contact. It may be that your contract with LPR does not currently include this additional service, and an amendment may be necessary.

The TREATED pallets complying with ISPM15 are subject to specific procedures and logistical measures of heat-treatment, marking, sorting and stock management.

The TREATED pallets must be heat-treated by an operator duly authorised by the national authorities. Pallets are heated to a minimum temperature of 56 °C for a minimum duration of 30 continuous minutes. This must be achieved throughout the entire profile and the core of the wood. This process is both time and energy consuming. The additional cost for TREATED pallets can be provided by your usual LPR sales contact.

No certificate or similar documentation is required. The IPPC mark applied on the pallet is the proof that the internationally accepted phytosanitary measures have been applied (see Q1 for more details). As stated in the ISPM15, the application of this mark makes the use of a phytosanitary certificate unnecessary.

The delivery note of LPR will indicate that the pallets delivered are “TREATED” or “TRT”.