In the UK, e-commerce was responsible for €700billion of turnover in 2021.

92% of Brits now shop online, meaning more parcels being sent, creating new journeys to every corner of the world. The supply chain is has been massively affected by the accelerated move to online shopping as a result of the Covid-19 pandemic, and is rapidly adapting to new e-commerce delivery models.

Faced with this, supply chains are dealing with increased production and higher delivery volumes. Whether BtoB, BtoC or CtoC, the impact of e-commerce supply chains, has seen many becoming completely transformed as a result.

So, when we consider the relationship between e-commerce and the supply chain, what are the challenges? And more importantly, what are the solutions?

Quick Navigation:

I - The challenges of e-commerce on the supply chain

2 - Control inventory management

II - Optimising the supply chain for e-commerce

1 - Available inventory management

2 - Supply chain tools and software for e-commerce

III - Solutions to simplify e-commerce

1 - Low-emission modes of transport

2 - Adapting points of sale for e-commerce

3 - The location of suppliers and storage

I. The challenges of e-commerce on the supply chain

1. Ensuring Delivery

Fast and efficient delivery is one of the main challenges as a result of e-commerce.

1.1. Speed of delivery

Delivery is a fundamental element for consumers. Choice, price and delivery time can influence their decision to buy. A reliable delivery service can be a key element of the transition from initial purchase to continued customer loyalty.

54% of consumers would like the option of delivery in less than an hour in urban areas. The e-commerce giant Amazon has led the march to ever faster delivery times, by offering UK delivery in less than 24 hours.

1.2. Diverse delivery methods

E-commerce delivery methods are numerous and can be adapted to meet customer needs, but this often complicates the supply chain.

Home delivery, locker pick up and even drive-in delivery points are multiplying. E-merchants must be ready to offer these continuously increasing options, whilst still working within ever shorter deadlines.

Consumers now expect both the e-merchant and themselves to be able to track goods in real-time.

1.3. The last mile

The last mile refers to the final phase of package delivery. It is the most expensive and the most polluting phase. On its own, it represents up to 20% of the price of transporting a product.

In order to improve profitability, e-merchants must try to optimise the costs of their last mile deliveries.

Finding environmentally friendly solutions for the last mile not only appeals to consumers but can also help to reduce supply chain costs. Options such as electric cars or bicycle delivery services can be used to help cut costs.

1.4. Meeting customer expectations

Consumer satisfaction stems from their experience with the merchant. Retaining existing customers, whilst converting browsers into new customers is essential to grow both the business and its online reputation.

Once an order has been placed, the merchant needs to ensure that the processing of the order through its supply chain and onto the selected delivery channel is seamless for the customer.

1.5. CSR, a growing concern

More and more customers consider country of origin, as well as production methods, packaging, and delivery methods when purchasing. 70% of online buyers favour websites promoting an ecologically-responsible approach (according to the KPMG / Fevad survey conducted in 2020).

A more environmentally friendly mindset can help your business to become more competitive and improve the image of your brand.

In an e-commerce context, this could mean using low-emission transportation (bicycles, electric vehicles), reducing packaging or even localising production where possible.

1.6. Delivery tracking

Customers now expect to know when their item will be delivered before they order. This requires prediction on the part of the company to estimate their delivery time.

Customers also want to be able to follow the progress of their order. A transport management system is essential to be able to collect and transmit information. Companies like Shippeo provide real-time visibility of transport and therefore make the supply chain more efficient.

1.7. After-sales service and returns management

The law provides for all consumers a period of 14 days in which the customer can cancel or return their purchase.

25% of products purchased on the Internet are returned. This creates additional transport flows and complicates the supply chain. To satisfy consumers, returns management must be fast and efficient. Returned orders require effective management systems, a smooth after-sales service and optimised warehouse operations.

The nature of returns means that it is not a straightforward process. Some returns are because they are not suitable or not required, others due to damage or malfunction. Returns into the warehouse will need to be separated and sorted into those that can be restocked, and those that will need to be recycled or disposed of.

Some e-commerce companies have created specific platforms for returns so they are outside of their main distribution platform. Today, solutions such as Reverse.io or JCD Logistique exist to simplify the after-sales experience for consumers and distributors. SaaS or outsourcing solutions allow you to control and optimise your supply chain automatically and efficiently and to reduce the costs related to the logistics of returns.

2. Control inventory management

Good inventory management is essential to ensure the proper functioning of the e-commerce supply chain.

2.1. Stock control

Ensuring that your business has sufficient product to meet demand is essential.

Insufficient product in stock can lead to out-of-stock situations. In turn, this can lead to potential customers not placing orders, and the risk that they will do so from a competitor.

On the contrary, if the quantities produced are too large, goods turn into dormant stock which negatively impacts the company:

-

Representing a significant storage cost

-

Tying up capital that could have been invested in a more profitable project or product (or simply kept as cash).

-

Causing a loss of warehouse space that could be allocated to a product with a better rotation.

It is therefore vital to be able to forecast product demand, to anticipate orders and optimise your supply chain.

2.2. Manage activity peaks

E-commerce can be affected by seasonality, as well as events such as:

-

Back to school

-

Mother's Day, Father's Day

-

Christmas

-

The health crisis

-

Wars

Marketing events such as Black Friday, sales, private sales and Cyber Monday create significant demand leading to an increase in orders for companies.

To be able to fulfil these orders, stock levels will need to be increased – it can also be an opportunity to sell off unsold stock. To meet all of these demands, the e-merchant must therefore continually anticipate and adapt their supply chain to these peaks (while trying to maintain their margin).

II. Optimising the supply chain for e-commerce

As we’ve covered above, e-commerce creates new logistical challenges. Let's explore the solutions that already exist to improve supply chain management in e-commerce.

1. Available inventory management methods for e-commerce

There are several inventory management methods that are suitable for e-commerce. Here are the 3 most common.

1.1. Dropshipping

Dropshipping is a management method that does not require stock or inventory.

In this case, the e-merchant only buys the product once the customer has placed an order. It is not the merchant who manages the shipment, but a wholesaler or the manufacturer.

The main advantages are the reduced need for storage space, inventory management and handling. Higher delivery costs for this system can mean lower profitability.

This method is only relevant if you have a reliable supplier who can handle unit parcel deliveries.

This option is increasingly singled out for its lack of ethics, product customisation, quality, and its poor customer experience. As an e-merchant, you do not have control over the quality of the product upstream and you will never be able to ensure the complete conformity of the product before it is sent to your customer.

1.2. JIT - Just in time

Also called the “re-order point method”. It is based on the principle of critical stock. This means you have the right stock in the right place at the right time. The goal is to never have dormant or deteriorated stock.

With this method, you reduce your stocks and storage costs to a minimum by producing the right quantity of product at exactly the right time. This requires specialised logistics and fluid organisation between your suppliers and your customers.

With this system, it is possible to adjust stock levels on demand. However, you may be caught off-guard if demand is higher than anticipated and you run the risk of running out of stock.

1.3. On-demand forecasting

On-demand forecasting allows you to manage your stocks according to the forecasts made on your products according to trends, seasonality, etc. These forecasts are based on your historical sales data to predict future demand.

This method makes it possible to seize new opportunities in the market and anticipate problems before they arise. The e-merchant can plan a production volume higher or lower than normal and manage supply. The goal is to maintain a stock as low as possible, but which is still able to meet consumer demand.

On-demand forecasting requires a reliable database and data without risk of assumption. If everything is done correctly, it is a very efficient form of inventory management for your supply chain.

There are other methods such as FIFO (first in, first out), or LIFO (last in, first out) that are covered in our article dedicated to the different methods of inventory and supply chain management.

2. Supply chain tools and software for e-commerce

Faced with these new challenges, software and tools have emerged to manage e-commerce supply chains. They are essential for carrying out forecasts and logistics planning.

2.1. The rolling forecast

Synonymous with forecasting, the rolling forecast is a management tool that provides a provisional schedule that is updated in real-time.

This tool allows optimal management in a constantly changing environment thanks to high precision forecasting demands.

It allows more flexibility and is more agile than traditional management tools. The rolling forecast, by improving stock management, improves budget forecasts and company performance.

Forecasts can be made for the short, medium or long term.

2.2. ERPs

ERPs (Enterprise Resource Planning) are software used to manage and centralise all the activities of a company.

They are essential for visualising and optimising production performance and costs. ERPs make it possible to effectively control inventory management, and to plan, anticipate and react quickly to unforeseen events.

The objective of inventory management ERPs is:

-

to have a centralised view of your stocks

-

to view and manage orders in real-time

-

to know the state of stocks instantly

-

to improve the traceability of products in your supply chain

There are many ERPs for inventory management: Dolisim, Openconcerto, etc.

2.3. APS software

APS software (Advanced Planning Systems) aims to help decision-making in business.

They allow management to have a closer view of the current position and affords greater flexibility and responsiveness. Thanks to APS, the supply chain is organised in such a way as to be able to respond to consumer demand while integrating all the key stages of the supply chain (purchase, production, storage, distribution, transport, etc.).

The data processed by the APS helps e-merchants to allocate available resources to efficiently process consumer requests.

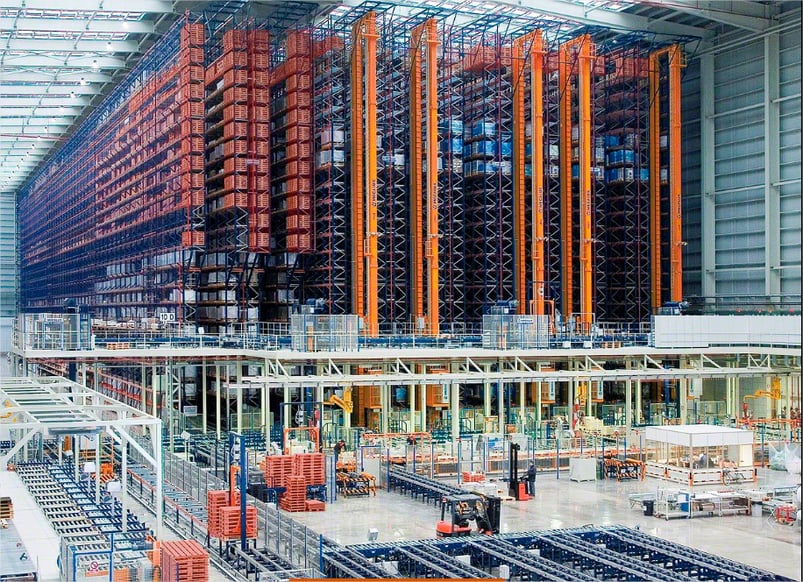

2.4. WMS and TMS

WMS (Warehouse Management Systems) and TMS (Transport Management Systems) enable warehouse and transport management.

WMS is software designed to manage all of the logistics processes of an automated warehouse (supply, inventory management, transfer, order preparation, shipments, etc.).

All arriving and despatched goods are recorded by the WMS providing an accurate view of stocks in real-time. You can also control the internal operations of your warehouse and optimise its operations.

TMS software has features dedicated to the management of freight transport. It improves the traceability of your transport flows and their organisation. Reducing transport costs is at the center of TMS software.

Through TMS software, you can organise your supply and delivery schedules, optimise the management of your vehicle fleet, track goods in real-time or prepare invoices.

Accurate data analysis allows for clearer decision making.

These two types of software are often used in a complementary way to maximise the performance of the supply chain.

III. Solutions to simplify e-commerce

New solutions have emerged to simplify and make e-commerce and supply chains even more efficient.

1. Low emission modes of transport

Using low-emission modes of transport makes it possible to limit the costs linked to e-commerce.

Using electric vehicles makes delivery greener. For example, Picnic, the European leader in the distribution of food products on the internet, is optimising its deliveries district by district by using electric carts.

Delivery by bicycle, particularly for the last mile, helps to enhance your brand image and reduces environmental impact. For example, Appli Colis offers urban delivery for small to medium-sized packages.

This low-emission transport makes it possible to anticipate and adapt to cities with Low (and Ultra Low) Emission Zones.

2. Adapting points of sale for e-commerce

Many changes have been made to simplify and secure deliveries.

You can now find order collection lockers in town centres, train stations and even shopping centres. The customer can efficiently retrieve their parcels using a code issued by the sender. This frees operators from pick-up validations, declutters storage spaces and improves overall customer satisfaction.

Mobile technologies are now available to help senders prepare orders. Using a smartphone, tablet, or smartwatch, they allow orders to be prepared and provide information on status in real-time, allowing better responsiveness.

3. The location of suppliers and storage

The location of suppliers and storage is important because it impacts the efficiency of delivery in e-commerce.

By choosing storage spaces that are closer to customers, distances between warehousing and customers are reduced, as are delivery times and costs. In addition, it allows for greater responsiveness in the event of unforeseen circumstances. Where possible, pooling the costs of a warehouse with another company in a similar sector in order to have a wider geographical coverage provides for a lower overall cost.

4. Delivery optimisation

Finally, the optimisation of deliveries creates better efficiencies, and reduces costs, leading to increased customer satisfaction.

Delivery can be improved through 3 main factors:

-

Traceability: real-time tracking of goods. This information makes it possible to offer better follow-up to the customer and better anticipation of deadlines, whilst reducing the risk of lost goods. Solutions such as RFID chips or the Shippeo platform offer improvements in traceability.

-

Loading: adapting your product and your packaging to your different delivery types can improve your loading. Optimising the way that trucks are filled can help to reduce delivery costs. Furthermore, thanks to cargo planning, operators can prepare, load and unload trucks more quickly.

-

Route selection: By optimising delivery routes using transport management software, you can reduce delivery times and related costs. Optimisation of journeys also makes it possible to reduce empty miles. It costs you less and is more environmentally friendly.

To conclude, in recent years, the growth of e-commerce has greatly impacted the world of logistics and supply chains.

With demand moving towards ever more precision and speed, companies must meet the new challenges as they arise. The supply chain is becoming ever more efficient and better connected.

However, the world of logistics must also face its responsibilities and move towards more sustainable consumption patterns. E-commerce raises crucial questions, with overconsumption and environmental impact at the heart of the debate.

The real challenge for the e-commerce supply chain is achieving a gradual transformation that combines growth and sustainability at the same time.

If you would like to discuss your logistics issues with our business experts, you can contact them here. You can also access our other blog articles to learn more about the supply chain and pallet pooling.