First used in the 1940’s, the pallet has established itself as the most practical and optimal means of transporting goods around the world. So much so that today, all companies that send, receive, or even store goods use them. Each year hundreds of millions of pallets are transported across continents around the world.

In order for the pallet to become a true standard in logistics, we had to think about the best way to manage their movement. Even today, many companies still buy their own pool of pallets, forcing them to control their daily management: transport, repairs... and the significant management costs related to their purchase or storage.

This is why at LPR - La Palette Rouge, we believe that pallet pooling is the best solution available. Before we explore the details, let's start by getting a better understanding of exactly what pallet pooling is.

Quick Navigation:

1 - Pallet pooling: definition

3 - Pallet pooling with LPR - La Palette Rouge

I - Pallet pooling: definition

Pallet pooling in the simplest sense, is a pallet rental and management system. This system allows companies to rent pallets, instead of buying them, reducing their logistics costs thanks to the pooling of pallets in different parts of the supply chain: producers, distributors, carriers, etc.

Opting for a pallet pooling solution avoids the purchase of pallets altogether and eliminates storage costs. A company no longer needs to have its own pool of pallets, or the costs and storage incurred by owning them. Pallets are only delivered according to their needs, which helps to reduce costs over time.

Pallets are no longer a product that is purchased. They are delivered and treated as a service. Think of them as ‘Pallets as a service’.

The pallet pooling company (or pooler), such as LPR - La Palette Rouge, is responsible for the pallets in the pool, ensuring their quality, their sourcing, their maintenance, their timely delivery and their collection after use.

More economical, more environmentally friendly, and more flexible, pallet pooling has established itself as a truly sustainable pallet management system. It makes it possible to meet current industry challenges, whilst improving the profitability of supply chains.

1 - The pallet pooling cycle

Pallet pooling is based on the principle of a circular economy and so works as a closed circuit. So, after sending us your specific pallet needs, we deliver them directly to your production sites.

Once the pallets have been used and sent to your distributors, we then collect them directly from your distribution points and transport them to our service centres. Once , they are repaired and returned to the circuit, ready for reuse.

II - Why use pallet pooling?

Although pallets are now the standard in logistics, their ownership and management can be a significant investment for a company, often taking up valuable time and resources. They often serve as a distraction, stopping companies focusing on their core business activities.

1 - Buying pallets: the disadvantages

a - Costs related to purchase, storage and repair

Buying an entire pool of pallets can have huge financial implications for a company. In addition to the costs associated with the purchase of the pallet pool, it is important to consider all the other expenses that ownership of a fleet entails:

-

Storage Costs - pallets take up space in warehouses when not in use.

-

Logistics Costs - management of the pallet pool which can quickly increase when there is a shortage of pallets for example.

-

Repair Costs - repair of pallets, or their replacement, when it is not possible to repair them.

b - Resources related to administrative management

Beyond the financial implications, the process of buying pallets is also a considerable waste of your team’s time. The administration and management of pallets can quickly turn into a real headache, forcing you to assign a significant proportion of your team’s time to their management.

2 - Pallet pooling : the advantages

a - Transparency and cost reductions

Effective management requires clarity. The information you receive must be clear, to ensure that you are able to identify any savings you can make. An informed decision is a good decision.

Pallet pool management often has many unforeseen costs: purchase, repair, exchange of pallets, etc.

That is why we believe transparency must be at the heart of pallet pooling. Clear forecasts and invoices allow you to make informed decisions for your business.

b - A flexible and responsive logistics management system

Another advantage of pallet-pooling is its great flexibility.

Whether your demand for pallets increases or decreases, you can rest assured that you will always have the right number of pallets to service your needs. You will no longer have to worry about unused pallets at the back of your warehouse, or a lack of availability during an increase in activity.

It only takes a few clicks to update your requirements and have new pallets delivered

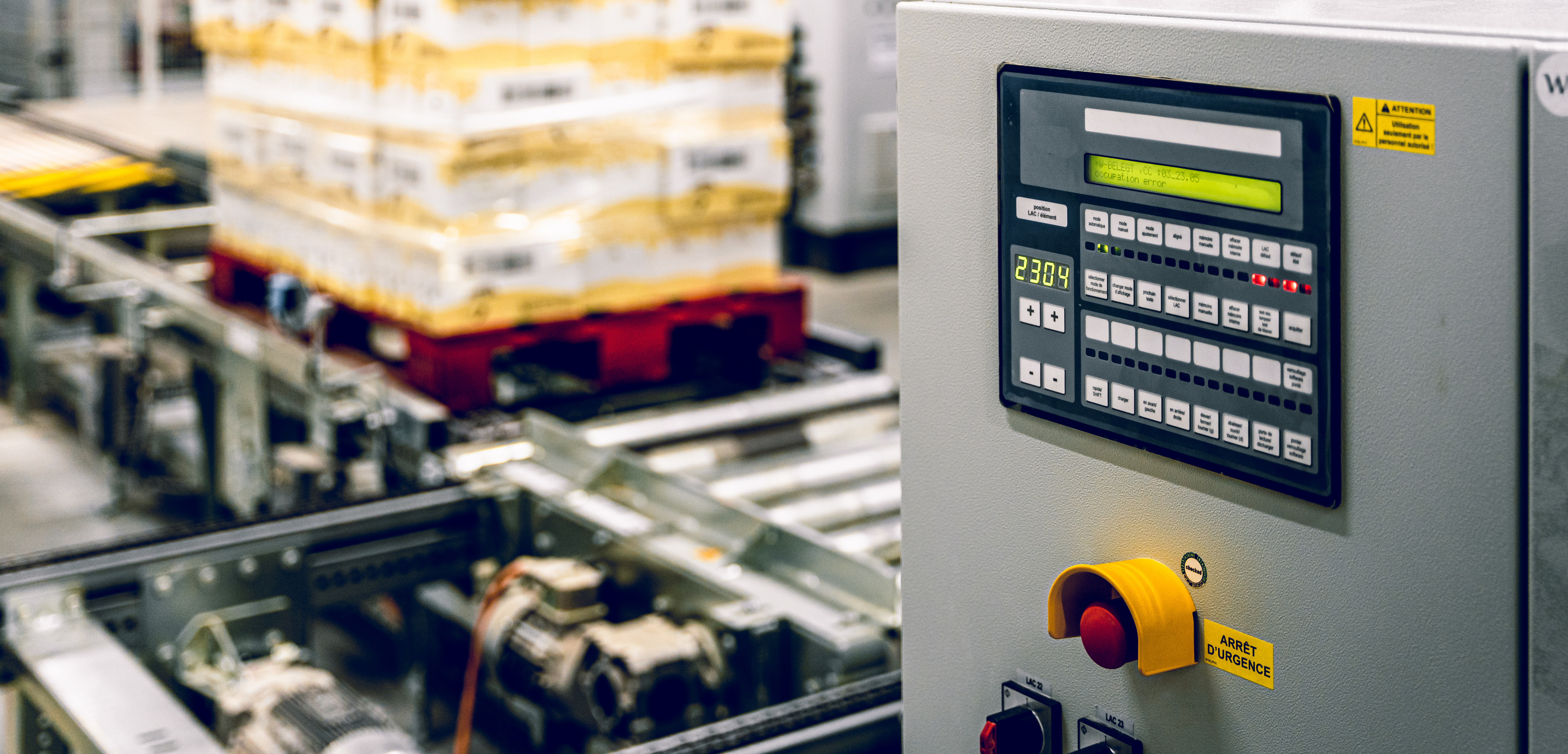

c - Simplified automation of the entire supply chain

Pallet pooling makes automation of your supply chain simple.

Say goodbye to refused deliveries and broken pallets!

In a pallet pooling system, all pallets are regularly inspected and repaired before being put back into circulation. This ensures they are always in ready to sue in your automated handling and storage logistics systems.

d - For a supply chain that reduces environmental impact

In addition to these advantages, pallet pooling promotes sustainable development. With pallet pooling, all pallets are repaired after use, ready to be reused and have a much longer lifespan than traditional pallets (5 years on average).

Having more sustainable pallets reduces the need for the resources necessary for their manufacture, meaning less wood used, a reduction in CO2 emissions and less waste involved in their production.

Choosing pallet pooling is a win-win decision, which benefits both your company and the environment.

III - Choose pallet pooling with LPR - La Palette Rouge

Why should you choose LPR - La Palette Rouge to supply pallet pooling for your supply chain?

1 - We take time to get to know your organisation

For us, getting to know your business and how it operates is the first step.

We then work to understand the specific requirements and challenges of your business to provide you with a bespoke solution.

After carrying out a detailed analysis of your logistics processes, we will offer you a tailor-made solution, fully adapted to your company’s requirements.

2 - We adapt to your processes

Switching to pallet-pooling with LPR – La Palette Rouge, is simple.

We adapt to your way of working - rather than the other way around. We take into account your needs and constraints, offering solutions that work with your business, just in a more efficient manner.

After carrying out a detailed analysis of your logistics processes, we will offer you a tailor-made solution, fully adapted to your company’s requirements.

3 - We have designed a proprietary management tool – allowing you to manage your account - from end to end

LPR has designed its own web interface (MyLPR). Powerful and intuitive, you can use MyLPR to view and manage every element of your account wherever you are, at a time to suit you!

Additionally, your dedicated account manager is always here to help, from setup to delivery!

From ordering your pallets to their collection by our carriers, LPR offers you a complete logistics optimisation solution. Make an appointment with one of our advisors to discuss your needs today!