- What we do

- Work with us

- Pallet overview

- About LPR

- Sustainability report 2022

- Foreword CEO Gerjo Scheringa

- Strategy business reporting

- Strategy delivering sustainability at scale

- Goals and results

- Brand ambassadors

- Sustainable change agents

- Employee health, training & development

- Green transport

- Lowering temperature washing

- Energy efficiency

- Nestlé sector collaboration

- Automation by Tanzer Solutions

- Aldi UK sustainability solutions

- Stakeholder management

- About Euro Pool Group

- Sustainability report 2021

- Sustainability

- About Us

- Research and development

- Safety and security

- Sustainability report 2022

- More

- MyLPR

- Contact

Sustainable development

at LPR

Sustainable development is a major component of LPR's DNA. We are proud to be able to help our customers to have an ever more responsible supply chain and build a more virtuous world together.

By using LPR's pallet rental and management service, your company can significantly reduce its carbon footprint. Simulate the greenhouse gas emission savings you could achieve by working with us.

The circular economy at LPR

Find out how our solution can help you reduce your carbon footprint and how it contributes to the transition to a circular economy. The circular economy promotes the reuse of resources and moves away from empty or under-optimised transport.

CSR efforts recognized by ECOVADIS

LPR has been recognized for its environmental, social, and responsible actions in the day-to-day performance of its activities. With its "Platinum" rating, LPR is among the top 1% of companies in terms of CSR performance.

CO2 reduction simulator

Evaluate the CO2 savings you could achieve by switching from a pallet exchange system to pallet rental and management.

Transport plan

We calculate and organise each pallet movement in order to better control them. We reduce the number of kilometres travelled thanks to the implementation of optimised, shared and multimodal transport plans.

Responsible wood sourcing

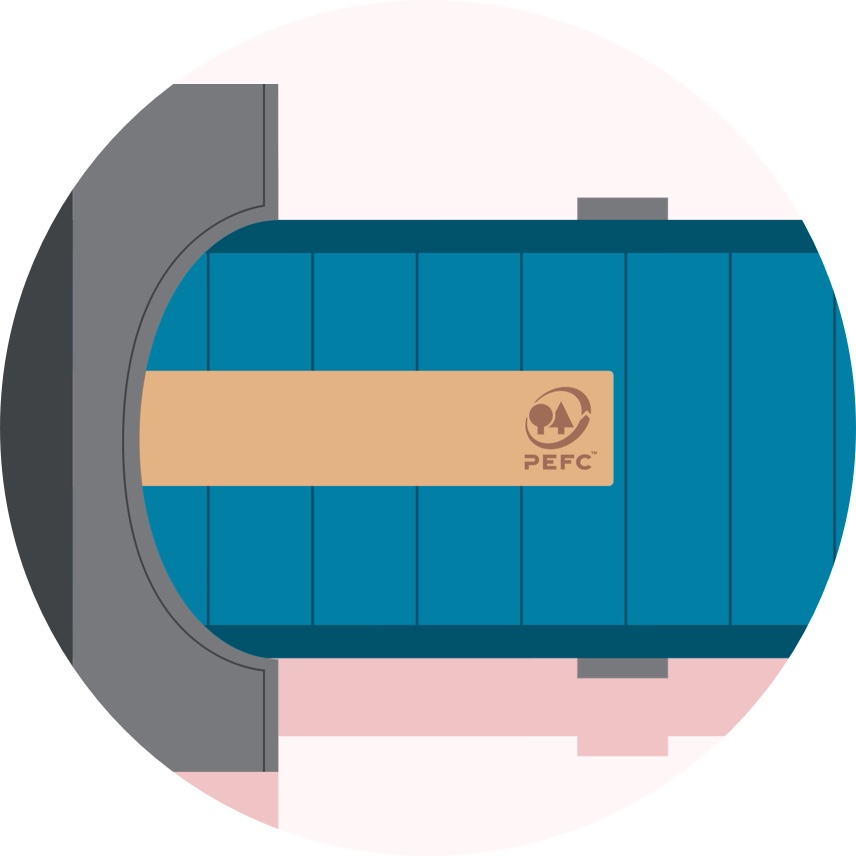

We ensure that the wood used to produce and repair our pallets comes from forests that are managed in an environmentally and socially responsible manner. For that reason, we are certified PEFC Chain of Custody since 2010 (PEFC logo licence No: PEFC/10-31-1869 ). Check the LPR Wood Sourcing Policy for more information.

Route optimisation

Transport represents an opportunity to reduce our greenhouse gas emissions by optimising the loading of our trucks, using the same carriers for inbound and outbound flows and in using multi-modal transport such as rail-road.

Reuse

Our pallets are reused and rotated several times a year. Returned pallets are checked, sorted and repaired before each new use. Our pallets have a lifespan of at least 5 years, and we manage them until the end of their usable life. Pallets that are no longer repairable are recycled.